How Fixed Navigation Decoy Equipment Enhances Safety Standards in Electrical and Electronic Manufacturing

2025-01-10

How Fixed Navigation Decoy Equipment Enhances Safety Standards in Electrical and Electronic Manufacturing

Table of Contents

- 1. Introduction to Fixed Navigation Decoy Equipment

- 2. The Importance of Safety in Electrical and Electronic Manufacturing

- 3. Understanding Fixed Navigation Decoy Equipment

- 4. How Fixed Navigation Decoy Equipment Works

- 5. Benefits of Using Fixed Navigation Decoy Equipment

- 6. Implementing Fixed Navigation Decoy Systems in Manufacturing

- 7. Challenges and Solutions in Deploying Navigation Decoy Equipment

- 8. The Future of Safety Standards with Navigation Decoy Equipment

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Fixed Navigation Decoy Equipment

In the rapidly advancing field of electrical and electronic manufacturing, ensuring safety standards is paramount. Fixed navigation decoy equipment has emerged as a pivotal technology in enhancing workplace safety. This article delves into how these systems contribute to safer manufacturing environments, significantly reducing risks associated with electrical and electronic production processes.

2. The Importance of Safety in Electrical and Electronic Manufacturing

Safety is not just a regulatory requirement; it is a fundamental aspect of operational excellence in the electrical and electronic manufacturing sector. High-voltage equipment, intricate wiring systems, and the use of hazardous materials make this industry particularly vulnerable to accidents. Implementing robust safety measures protects employees and ensures compliance with industry regulations.

Preventive measures such as advanced safety equipment and training protocols are crucial in mitigating risks. As technology evolves, so too must our approach to safety. Fixed navigation decoy equipment stands at the forefront of these advancements, providing innovative solutions to longstanding safety challenges.

3. Understanding Fixed Navigation Decoy Equipment

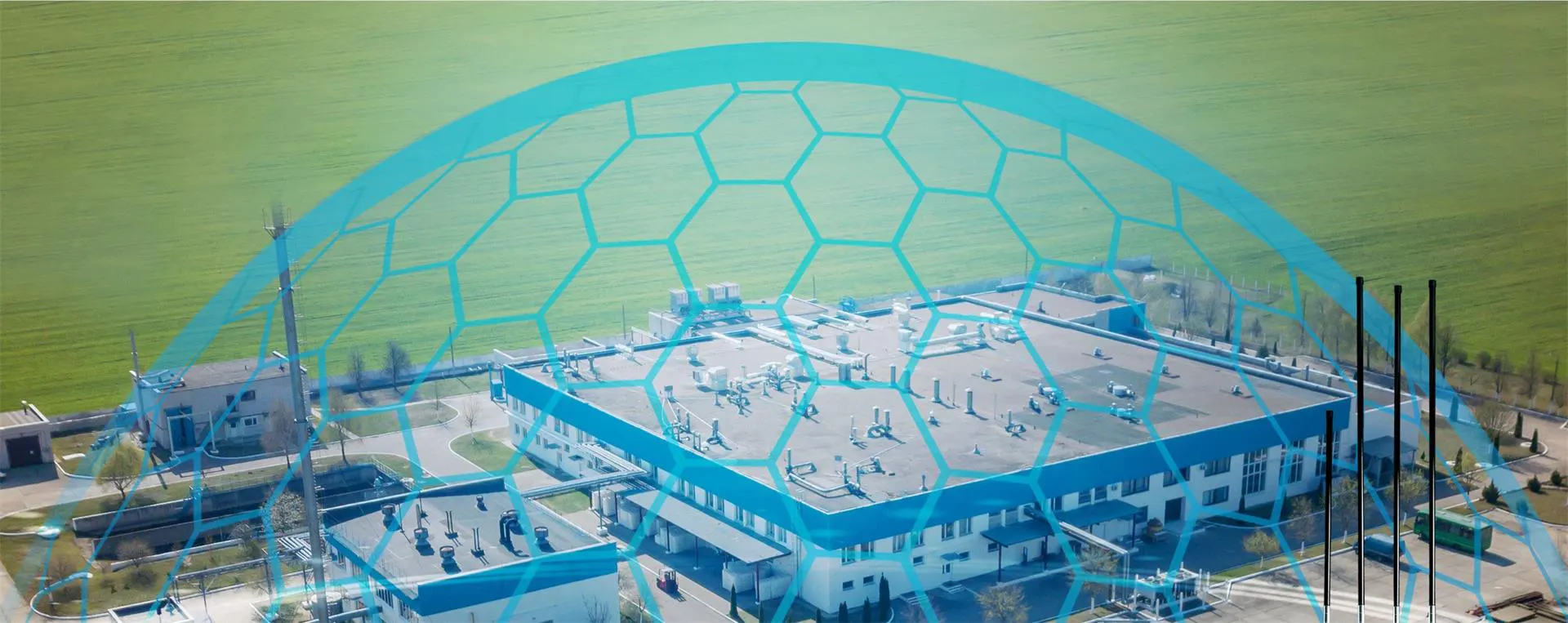

Fixed navigation decoy equipment refers to specialized systems designed to create safe operational zones within manufacturing facilities. These systems use advanced technology to guide operators and machinery safely around hazardous areas. Through visual and auditory cues, they help prevent accidents and ensure that employees adhere to safety protocols.

This equipment can be integrated into various manufacturing processes, including assembly lines and testing facilities. By establishing clear navigation pathways, fixed navigation decoy systems minimize the risk of collisions and other safety incidents.

4. How Fixed Navigation Decoy Equipment Works

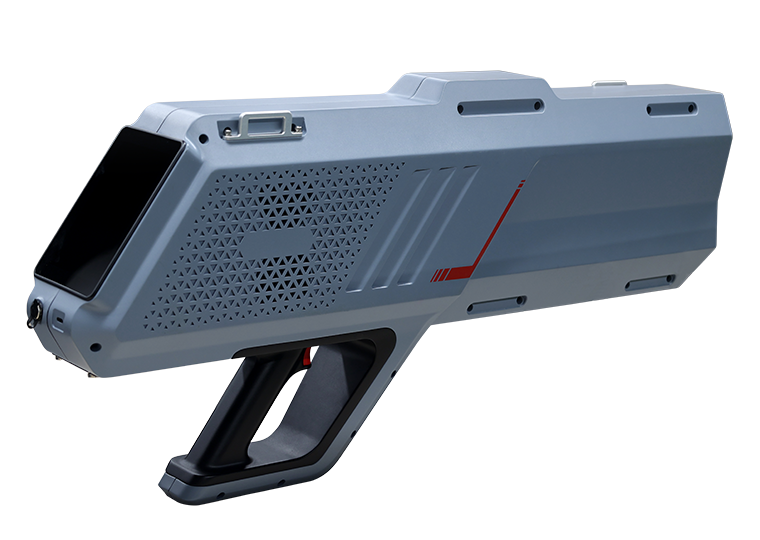

Fixed navigation decoy systems utilize a combination of sensors, cameras, and signaling devices. Here’s a breakdown of how these components work together:

4.1 Sensor Technology

Sensors are installed throughout the manufacturing facility to monitor movement and detect the presence of personnel and machinery. This real-time data allows the system to react quickly to potential hazards, sending alerts to operators and automatically adjusting navigation paths.

4.2 Visual Signaling

Visual signals, such as LED lights or digital displays, guide employees and equipment through safe pathways. These signals are designed to be highly visible, even in low-light conditions, ensuring that all personnel can easily identify safe zones.

4.3 Auditory Alerts

In addition to visual cues, auditory alerts provide an extra layer of safety. These can include alarms, voice prompts, or other sound notifications that indicate when an individual is entering a hazardous area or when equipment is in motion.

5. Benefits of Using Fixed Navigation Decoy Equipment

The integration of fixed navigation decoy equipment into manufacturing processes offers numerous benefits, enhancing the overall safety landscape.

5.1 Enhanced Safety Compliance

By providing clear guidelines and alerts, fixed navigation systems improve compliance with safety regulations. This proactive approach reduces the likelihood of accidents and helps organizations avoid costly fines and legal issues.

5.2 Reduced Accident Rates

The primary benefit of fixed navigation decoy systems is the significant reduction in workplace accidents. By minimizing human error and improving situational awareness, these systems protect employees from potential hazards.

5.3 Increased Operational Efficiency

With enhanced safety measures in place, employees can focus more on their tasks without the constant worry of accidents. This increased confidence leads to improved productivity and operational efficiency throughout the manufacturing process.

5.4 Training and Familiarization

Fixed navigation decoy systems can serve as training tools for new employees. By familiarizing them with safe pathways and operational zones, organizations can accelerate onboarding and ensure that all personnel are well-versed in safety protocols.

6. Implementing Fixed Navigation Decoy Systems in Manufacturing

The successful implementation of fixed navigation decoy systems requires careful planning and execution. Here are key steps to consider:

6.1 Assessing Facility Layout

Begin by evaluating the manufacturing facility’s layout. Identify high-risk areas and potential traffic zones where navigation decoy systems will be most beneficial.

6.2 Selecting Appropriate Technology

Choose the right technology that aligns with your facility's specific needs. Consider factors such as the type of equipment used, the size of the manufacturing area, and the level of automation.

6.3 Training Staff

Provide comprehensive training for all employees on using the fixed navigation decoy systems. This includes understanding visual and auditory signals and adhering to established safety protocols.

6.4 Monitoring and Continuous Improvement

After implementation, continuously monitor the effectiveness of the systems. Gather feedback from employees and make necessary adjustments to improve safety measures continually.

7. Challenges and Solutions in Deploying Navigation Decoy Equipment

While fixed navigation decoy systems offer substantial benefits, challenges may arise during deployment. Here are common issues and potential solutions:

7.1 Integration with Existing Systems

**Challenge**: Integrating new navigation systems with existing manufacturing processes can be complex.

**Solution**: Conduct a thorough analysis of current systems and work with technology providers to ensure seamless integration.

7.2 Employee Resistance

**Challenge**: Employees may resist adopting new technology due to unfamiliarity.

**Solution**: Engage employees early in the process, providing training and demonstrating the benefits of the systems.

7.3 High Initial Costs

**Challenge**: The upfront cost of installing fixed navigation decoy equipment can be a barrier for some manufacturers.

**Solution**: Consider long-term cost savings associated with reduced accidents and improved efficiency to justify the investment.

8. The Future of Safety Standards with Navigation Decoy Equipment

As technology continues to evolve, the future of safety standards in the electrical and electronic manufacturing industry looks promising. Fixed navigation decoy equipment is expected to integrate with emerging technologies such as artificial intelligence and the Internet of Things (IoT). These advancements will enhance real-time monitoring and predictive analytics, further elevating safety standards.

Innovations in this field will also likely lead to the development of more sophisticated systems capable of adapting to dynamic manufacturing environments. As companies embrace these technologies, safety becomes not just a compliance measure but a core aspect of operational strategy.

9. Frequently Asked Questions

9.1 What is fixed navigation decoy equipment?

Fixed navigation decoy equipment is a safety system designed to guide personnel and machinery safely through manufacturing facilities, reducing the risk of accidents.

9.2 How does fixed navigation decoy equipment improve safety?

It enhances safety by providing visual and auditory cues that help operators navigate safely around hazardous areas, thereby minimizing human error.

9.3 What are the key components of a fixed navigation decoy system?

Key components include sensors, visual signaling devices, and auditory alerts, which work together to create safe operational zones.

9.4 How can I implement fixed navigation decoy systems in my facility?

Start by assessing your facility layout, selecting appropriate technology, training staff, and continuously monitoring the system for improvements.

9.5 Are there challenges in deploying fixed navigation decoy systems?

Yes, challenges include integrating with existing systems, employee resistance, and high initial costs. However, with proper planning and training, these challenges can be addressed.

10. Conclusion

In conclusion, fixed navigation decoy equipment plays a crucial role in enhancing safety standards in the electrical and electronic manufacturing industry. By reducing accident rates, improving compliance, and increasing operational efficiency, these systems represent a vital investment in the future of workplace safety. As technology continues to advance, the integration of navigation decoy systems will undoubtedly evolve, leading to even safer manufacturing environments. Embracing these innovations will not only protect employees but will also foster a culture of safety that can enhance overall productivity and success in the manufacturing sector.