2025-01-03

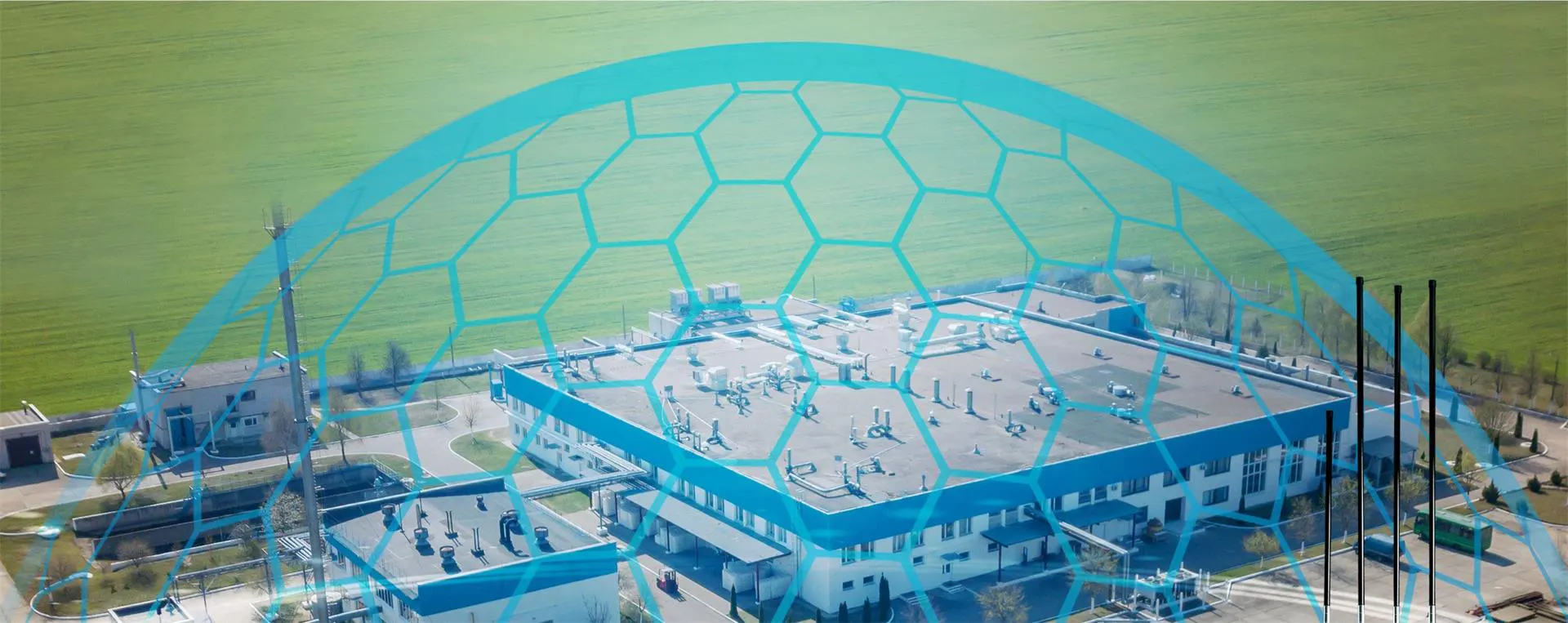

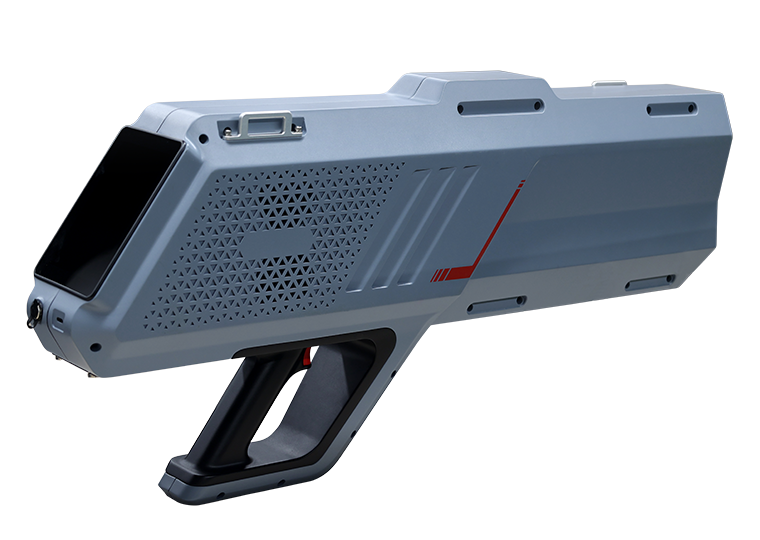

In the rapidly evolving field of electrical and electronics manufacturing, Portable FPV Detection Terminals are emerging as critical tools for ensuring safety and compliance. These devices are designed to provide real-time monitoring and detection capabilities, making them invaluable for professionals in the industry. By integrating technology that allows for immediate feedback and analysis, these terminals help technicians quickly identify issues related to equipment performance and electrical integrity.

One of the primary advantages of Portable FPV Detection Terminals is their ability to facilitate efficient inspections. Traditional detection methods often require cumbersome equipment and extensive manual checks, which can be time-consuming and prone to human error. In contrast, portable terminals offer streamlined solutions that improve the speed and accuracy of inspections. They allow electrical engineers and technicians to conduct assessments in diverse environments without the need for extensive setup or bulky equipment.

The functionality of these terminals includes advanced imaging technologies, such as infrared and thermal imaging, which can detect heat anomalies indicative of electrical issues or equipment malfunctions. Additionally, many terminals come equipped with wireless capabilities, enabling data collection and analysis in real-time. This feature is particularly beneficial for teams working on large-scale projects where immediate feedback can prevent costly downtime and ensure compliance with safety regulations.

Moreover, the versatility of Portable FPV Detection Terminals makes them suitable for various applications, from routine maintenance checks to emergency response scenarios. Their portable nature allows for easy transport across job sites, making them ideal for electrical contractors and field technicians who require reliable detection capabilities on the go.

As industries increasingly prioritize safety and efficiency, the demand for innovative detection solutions is expected to rise. The ongoing development in sensor technology and data analytics will further enhance the capabilities of Portable FPV Detection Terminals, making them even more integral to modern manufacturing processes.

In conclusion, the integration of Portable FPV Detection Terminals into the electrical and electronics manufacturing landscape represents a significant leap forward in operational efficiency and safety. Professionals in the industry should consider the adoption of these technologies to stay competitive and ensure high standards of quality and compliance. By embracing these advancements, businesses can not only enhance their inspection processes but also contribute to a safer working environment for all employees.

One of the primary advantages of Portable FPV Detection Terminals is their ability to facilitate efficient inspections. Traditional detection methods often require cumbersome equipment and extensive manual checks, which can be time-consuming and prone to human error. In contrast, portable terminals offer streamlined solutions that improve the speed and accuracy of inspections. They allow electrical engineers and technicians to conduct assessments in diverse environments without the need for extensive setup or bulky equipment.

The functionality of these terminals includes advanced imaging technologies, such as infrared and thermal imaging, which can detect heat anomalies indicative of electrical issues or equipment malfunctions. Additionally, many terminals come equipped with wireless capabilities, enabling data collection and analysis in real-time. This feature is particularly beneficial for teams working on large-scale projects where immediate feedback can prevent costly downtime and ensure compliance with safety regulations.

Moreover, the versatility of Portable FPV Detection Terminals makes them suitable for various applications, from routine maintenance checks to emergency response scenarios. Their portable nature allows for easy transport across job sites, making them ideal for electrical contractors and field technicians who require reliable detection capabilities on the go.

As industries increasingly prioritize safety and efficiency, the demand for innovative detection solutions is expected to rise. The ongoing development in sensor technology and data analytics will further enhance the capabilities of Portable FPV Detection Terminals, making them even more integral to modern manufacturing processes.

In conclusion, the integration of Portable FPV Detection Terminals into the electrical and electronics manufacturing landscape represents a significant leap forward in operational efficiency and safety. Professionals in the industry should consider the adoption of these technologies to stay competitive and ensure high standards of quality and compliance. By embracing these advancements, businesses can not only enhance their inspection processes but also contribute to a safer working environment for all employees.