Transforming Instrumentation with SDR C-UAV Digital Modules: Revolutionizing Non-Destructive Testing and Metal Detection

2025-04-04

Transforming Instrumentation with SDR C-UAV Digital Modules

In the world of instrumentation, innovation drives efficiency, accuracy, and safety. **SDR C-UAV digital modules** are at the forefront of this evolution, particularly in **non-destructive testing (NDT)** and **metal detection**. These cutting-edge tools harness the power of Software-Defined Radio (SDR) technology to deliver unprecedented capabilities in various applications. In this article, we will explore the transformative impact of SDR C-UAV digital modules, their applications, components, and future potential, while also addressing common queries related to this topic.

Table of Contents

- What is SDR C-UAV Technology?

- Benefits of SDR C-UAV Digital Modules

- Applications of SDR C-UAV in Instrumentation

- Key Components of SDR C-UAV Modules

- How SDR Technology Works

- Advantages of SDR in Non-Destructive Testing

- The Future of SDR C-UAV Digital Modules

- FAQs About SDR C-UAV Digital Modules

What is SDR C-UAV Technology?

**Software-Defined Radio (SDR)** technology enables the creation of radio systems through software rather than traditional hardware components. This flexibility allows SDR C-UAV (Control-UAV) digital modules to adapt to various operational scenarios and signal-processing tasks. Specifically designed for unmanned aerial vehicles (UAVs), these modules optimize signal reception and processing for tasks like **non-destructive testing** and **metal detection**. As a result, they offer significant advantages over traditional instrumentation methods.

Benefits of SDR C-UAV Digital Modules

The adoption of SDR C-UAV digital modules presents several key benefits:

1. Versatility

SDR technology allows for rapid reconfiguration and customization, enabling users to adapt the modules for different applications and environments seamlessly.

2. Enhanced Signal Processing

These modules leverage advanced algorithms for improved signal processing, leading to enhanced detection capabilities and data accuracy.

3. Cost-Effectiveness

By reducing the need for multiple specialized devices, SDR C-UAV modules lower overall equipment costs and maintenance expenses.

4. Real-Time Data Analysis

SDR technology enables real-time data streaming and analysis, providing immediate insights that can inform operational decisions.

5. Increased Safety

Utilizing UAVs equipped with SDR modules for NDT and metal detection minimizes risks related to hazardous environments, as operators can remain at a safe distance.

Applications of SDR C-UAV in Instrumentation

The applications of SDR C-UAV digital modules span various fields, with significant implications for **non-destructive testing** and **metal detection**.

Non-Destructive Testing Applications

**Non-destructive testing (NDT)** is critical for ensuring the integrity and safety of structures and materials without causing damage. SDR C-UAV modules enhance NDT processes through:

1. Improved Imaging Techniques

Using advanced imaging technologies, SDR modules can provide high-resolution images of materials, helping identify faults or imperfections.

2. Remote Inspection Capabilities

UAVs equipped with SDR technology can access hard-to-reach or hazardous areas, allowing for safer and more efficient inspections.

3. Data Fusion

SDR C-UAV modules allow for the integration of various data types, enhancing the overall understanding of material integrity.

Metal Detection Applications

In metal detection, SDR C-UAV modules offer substantial benefits, particularly in industries like construction, mining, and archaeology:

1. Increased Sensitivity

The use of SDR technology enhances the sensitivity of metal detectors, allowing for the detection of smaller or buried metal objects.

2. Integration with Geospatial Data

These modules can work alongside geospatial data systems, improving the accuracy of metal location and identification.

3. Enhanced Mapping Capabilities

SDR C-UAV modules can generate detailed maps of metal locations, facilitating more effective planning and operational execution.

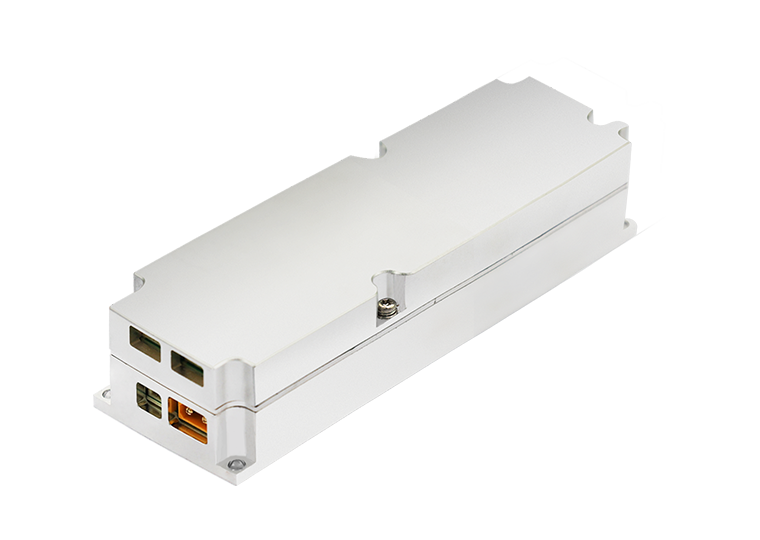

Key Components of SDR C-UAV Modules

Understanding the individual components of SDR C-UAV digital modules helps clarify their functionality and effectiveness.

1. RF Front End

The radio frequency front end is responsible for signal reception and transmission, ensuring optimal performance in various environments.

2. Digital Signal Processor (DSP)

The DSP handles the processing of received signals, applying algorithms to enhance data quality and accuracy.

3. Software Interface

A user-friendly software interface allows operators to configure and manage the SDR modules efficiently.

4. Power Supply

A robust power supply ensures uninterrupted operation, which is essential for UAV applications.

How SDR Technology Works

SDR technology operates by converting analog signals into digital formats for processing. Here’s a simplified overview:

1. **Signal Reception**: The RF front end captures incoming signals.

2. **Analog-to-Digital Conversion**: The analog signals are converted into digital formats for processing.

3. **Signal Processing**: The DSP applies various algorithms to analyze the data and extract meaningful insights.

4. **Output Generation**: The processed data is outputted through the software interface for user review and decision-making.

Advantages of SDR in Non-Destructive Testing

The integration of SDR technology into NDT practices presents several advantages:

1. Customized Solutions

SDR modules can be tailored to meet specific NDT requirements, optimizing performance according to material types and inspection parameters.

2. Greater Efficiency

The ability to conduct real-time analyses reduces downtime and streamlines operational processes.

3. Improved Compliance

With enhanced detection capabilities, organizations can better meet regulatory standards for material safety.

The Future of SDR C-UAV Digital Modules

Looking ahead, SDR C-UAV digital modules are poised to play a pivotal role in the advancement of instrumentation technologies. Anticipated trends include:

1. Integration with AI and Machine Learning

Combining SDR technology with artificial intelligence will enable more sophisticated data analysis, improving fault detection and predictive maintenance.

2. Expansion of Application Areas

As industries continue to innovate, the applications of SDR modules will extend into new fields, further enhancing their relevance in modern instrumentation.

3. Development of Advanced Algorithms

Ongoing research and development will lead to the creation of more effective algorithms for signal processing, expanding the capabilities of SDR technology.

FAQs About SDR C-UAV Digital Modules

1. What industries can benefit from SDR C-UAV digital modules?

SDR C-UAV modules can be utilized in various industries, including construction, aerospace, mining, and environmental monitoring.

2. How does SDR technology improve data accuracy?

SDR technology enhances data accuracy through advanced signal processing algorithms that filter out noise and improve detection capabilities.

3. Can SDR C-UAV modules be used for live monitoring?

Yes, SDR C-UAV modules are capable of real-time data streaming, enabling live monitoring of inspections and operations.

4. What are the safety benefits of using UAVs with SDR modules?

UAVs equipped with SDR modules allow operators to conduct inspections in hazardous areas without physical exposure to risks.

5. Are SDR digital modules cost-effective compared to traditional methods?

Absolutely. SDR technology reduces the need for multiple specialized devices, leading to lower overall costs and maintenance efforts.

Conclusion

The introduction of SDR C-UAV digital modules is revolutionizing the field of instrumentation, particularly in non-destructive testing and metal detection. By enhancing versatility, data accuracy, and safety, these innovative tools are poised to address the challenges faced by various industries. As we look towards the future, the continuous evolution of SDR technology will undoubtedly unlock even more potential applications and efficiencies, solidifying its role as a cornerstone of modern instrumentation practices. Embracing these advancements will not only enhance operational effectiveness but will also lead to safer, more reliable outcomes across various sectors.

Related News